Case history

Product and mould redesign and optimisation

CASE STUDY:

Product and mould redesign and optimisation

CLIENT:

Italian company operating in the lighting and emergency lighting sector

THE CHALLENGE:

Simplifying the initial design to reduce the number of parts while ensuring a high quality of the final product

VPLAST SOLUTION:

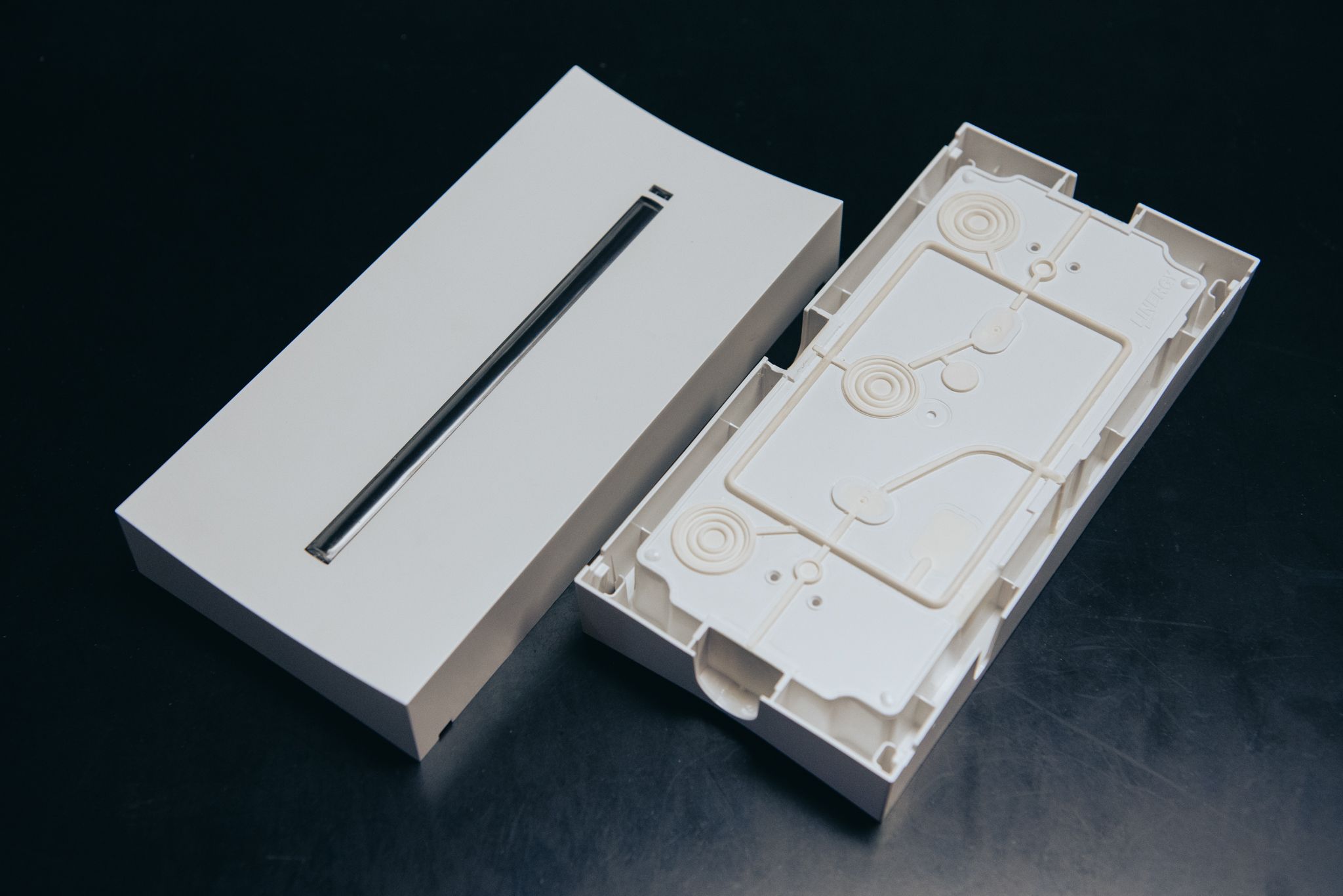

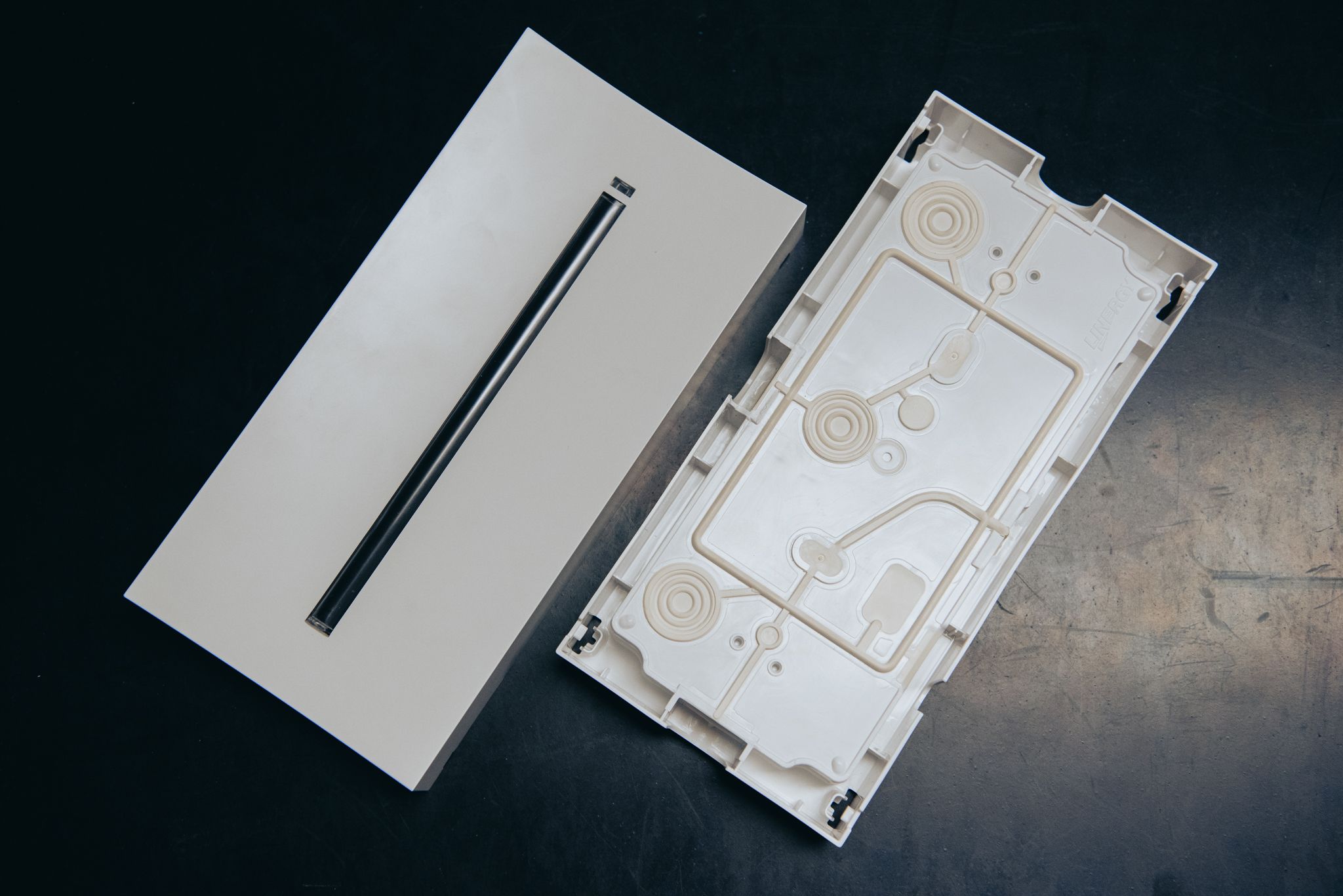

The initial design of this emergency luminaire presented a product consisting of six articles.

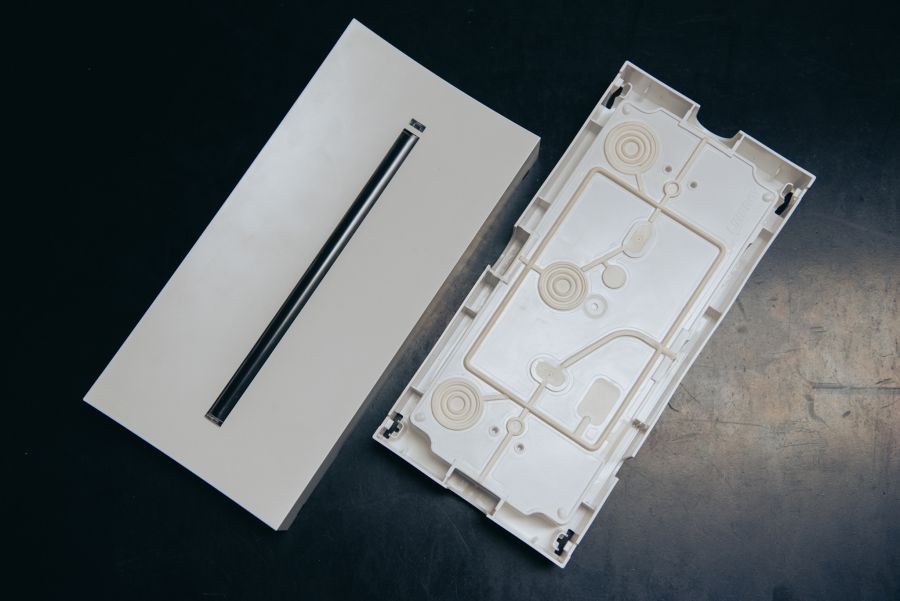

With a design study and the creation of new two-component moulds, we were able to reduce the number of parts from six to two, thereby optimising the cost of making the moulds.

In addition, a study was carried out to make the mould of the light guide part more efficient: while retaining the shape and material, the part, once made, had more lumens, guaranteeing better performance in use.

CLIENT BENEFITS:

- Mould optimisation

- Final product optimisation

- Higher-performance end product