News

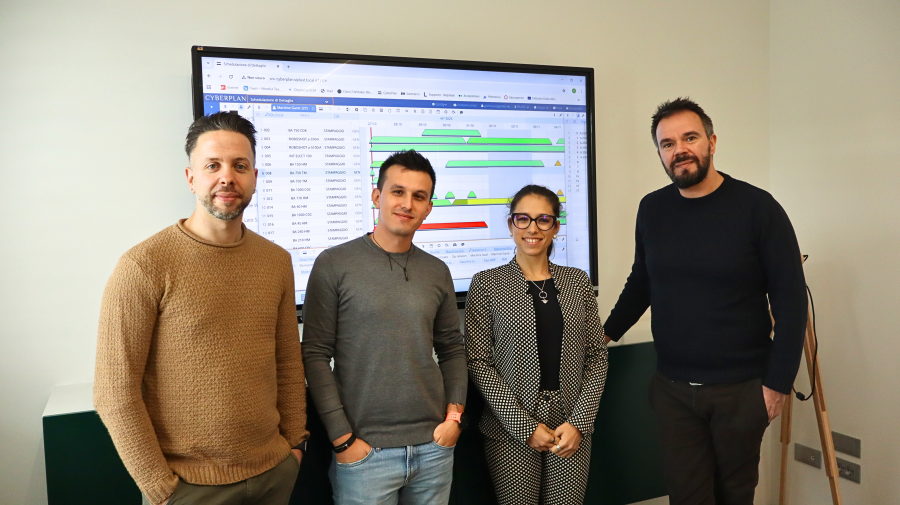

New APS software: Zucchetti's CyberPlan improves our production planning.

In recent years, the digitalization of production processes has become a key element in ensuring competitiveness, flexibility, and the ability to respond to market needs. With this in mind, our company has chosen to take a major step forward in planning management by switching from the current APS (Advanced Planning and Scheduling) by Siemens Preactor to the new Zucchetti CyberPlan

In this software transition, we were able to rely on Link Management, a management engineering firm specializing in organizing and improving production processes and the supply chain. Their professionalism, availability, and ability to offer concrete and customized solutions were the factors that convinced us to trust them and contributed to a successful collaboration.

Why this change?

After a careful analysis of our production flows and planning needs, we decided to adopt CyberPlan to rely on a more modern, integrated, and high-performance system.

The goal is to optimize production resource planning, improving visibility across the entire process and the ability to react in real time to changes in demand or production issues.

CyberPlan is currently one of the most advanced APS systems on the Italian market, capable of natively communicating with leading ERP and MES systems and offering advanced tools for simulating, analyzing, and visualizing production plans.

Expected Operational Benefits

With the implementation of CyberPlan, we expect to achieve concrete results on several fronts:

• More precise and dynamic planning, with real-time updates on the availability of materials, resources, and machinery.

• Reduced setup and downtime, thanks to intelligent optimization of production sequences.

• Greater forecasting capacity, through "what-if" analyses to assess the impact of changes or unforeseen events in advance.

• Smoother integration with other company systems, for consistent and coordinated data management.

• More effective decision support, thanks to intuitive dashboards and graphical tools.

An Investment for the Future

This transition represents not just a software change, but a strategic choice for digital evolution.

The adoption of CyberPlan is part of a broader technological and organizational transformation process aimed at making our company increasingly efficient, connected, and aligned with the principles of Industry 4.0.

We believe that innovation isn't just a matter of tools, but also of mindset and collaboration. For this reason, the introduction of CyberPlan is accompanied by significant internal training and engagement with the planning and production teams.

With this project, we are taking another step toward leaner, more transparent, and forward-looking production management.